Description

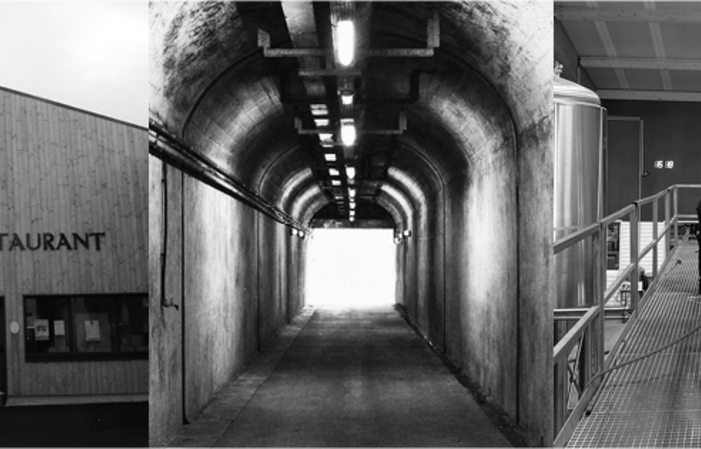

The Bout du Monde brewery is a craft brewery born in 2013, located in former NATO undergrounds in Terenez, in the heart of Finistère.

At the end of 2019, our brewery moved to the Quiella Artisanale Zone in Faou to set up its new manufacturing workshop, offices and a shop - bar - restaurant.

Our production capacity is 10 HL (1000 litres) per brew. Our beer needs time to express all its aromas and taste. The quality of our products is sealed by a manufacturing process that is constantly improved and which we will be happy to explain to you during your visit on site.

We work as soon as possible with suppliers as close as possible to our brewery. We forge long-term and local collaborations as for our packaging, our delivery services, our communication and the enhancement of our drèches.

Tours can be made from Brest from the Customs wharf and by sea, in partnership with the Brestoâ boat, Loch Monna.

Several beers ready to be tasted and many more to come. Our brewery is Breton but open to the world! We favour short circuits and independent dealers as well as human relationships which, in our eyes, are a strength.

Looking forward to welcoming you!

Rules and conditions

Due to the current health crisis, underground tours are suspended but we offer the presentation of our new premises every day from Tuesday to Saturday from 3pm (by reservation)

Alcohol-free for minors / Free for under-6s

Reservation policy

Cancellation policy: : Strict

Products offered for tasting:

La brasserie du bout du monde Professional seller

The history of the brewery Born in 2013, the Bout du Monde Brewery has established itself in former NATO undergrounds in Terenez, in the heart of Finistère. A craft brewery with a production capacity... See more

The history of the brewery Born in 2013, the Bout du Monde Brewery has established itself in former NATO undergrounds in Terenez, in the heart of Finistère. A craft brewery with a production capacity of 10 HL (1000 litres) per brew, which has grown very quickly. A craft brewery of 40 Hl At the end of 2019, the brewery moved to the Quiella Artisanale Zone in Faou to set up its new manufacturing workshop, offices and a shop - bar - restaurant. Today the brewery includes: a 40HL impatting tank, a boiling tank, a centrifuge tank (Whirlpool), two water storage tanks (one of cold water and one of hot water) of 80HL each and 4 fermentation tanks of 80HL. APPLATING The malt applate is the first step that takes place at the brewery. The malt is crushed into small pieces to leave the grain envelopes intact and release the starch from the grains. Crushed grains are called "milling." The ideal crush produces a lot of broken grains in 4-6 pieces, little flour, few whole grains and as little damage as possible to the bark of the grain. Too fine a grind will make filtration difficult. Conversely, if the grind is too large, the starch will not be accessible. The crushed malt is thus ready to be impaled in the brewing room. EMPATAGE/MONOPALIER This step involves mixing the water and the crushed malt. The purpose of this operation is to awaken the enzymes that will turn starch into sugar and dextrines. In terms of brewing methods, there are two: the multi-palier method and the single-palier method. Our brewery adopts the single-palier method. The water is introduced into the material vat and is heated to around 80oC. The grind is added to this tank and rests for an hour and a half. At the end of time, the saccharification is complete. This method is mainly used in England, hence the name of English or simple infusion. filtration Filtering is the separation of depleted grain debris (the grains) from the sweet liquid (must). Filtering takes place in two stages: At first, the envelopes of the malt grains are held by the double perforated bottom of the tank. The grain debris will then be deposited, so as to generate a filter layer. The must passes through this natural filter, loaded with sugars and dextrins. In a second step, the envelopes are rinsed with hot water to remove the maximum extract. This operation lasts between 1:30 and 2:30 a.m. depending on the level of clarification expected. After this stage, the grains are reused as cattle feed for the Angus du Cranou. See less

- ID Card:

- Email:

- Already rent: